Edge Banding 101

Plywood is one of the most economical building materials out there. It comes in various thicknesses, sizes, and species. Covering the edges can be a problem for some. The edges can be covered with small strips of solid wood to hide the layers but I am horrible at getting the strips to line up and be unnoticeable! Depending on the project, the edges can be thoroughly sanded and left exposed but sometimes I prefer a more finished look. That is where iron-on edge banding comes in. Let me show you how to apply edge banding to plywood…

I purchase mine from VeneerSupplies.com. Joe carries quite a selection of species at great prices! The service is unbeatable plus he carries Copper Veneer which looks really cool and I wish I could afford it! (I’m a HUGE fan!)

Anyway, applying edge banding is not hard at all but having the right tool (the edge banding trimmer) is the most important step! Some pieces such as doors and drawer fronts will need edge banding applied to all four sides. Other pieces will only need edge banding on exposed areas.

Today, I’ll show you how I applied edge banding to pieces of fabulous walnut plywood I’m going to turn into a cabinet (a post for later!).

Materials:

- Plywood

- Edge banding to match the plywood

- Edge banding trim tool

- Scissors

- Regular household iron

When using plywood in a project, it is best to apply the edge banding to each piece before assembly. I cut a couple of doors from the walnut plywood and need to apply the edge banding to it. I like to apply the edge banding to the sides first, then to the top and bottom.

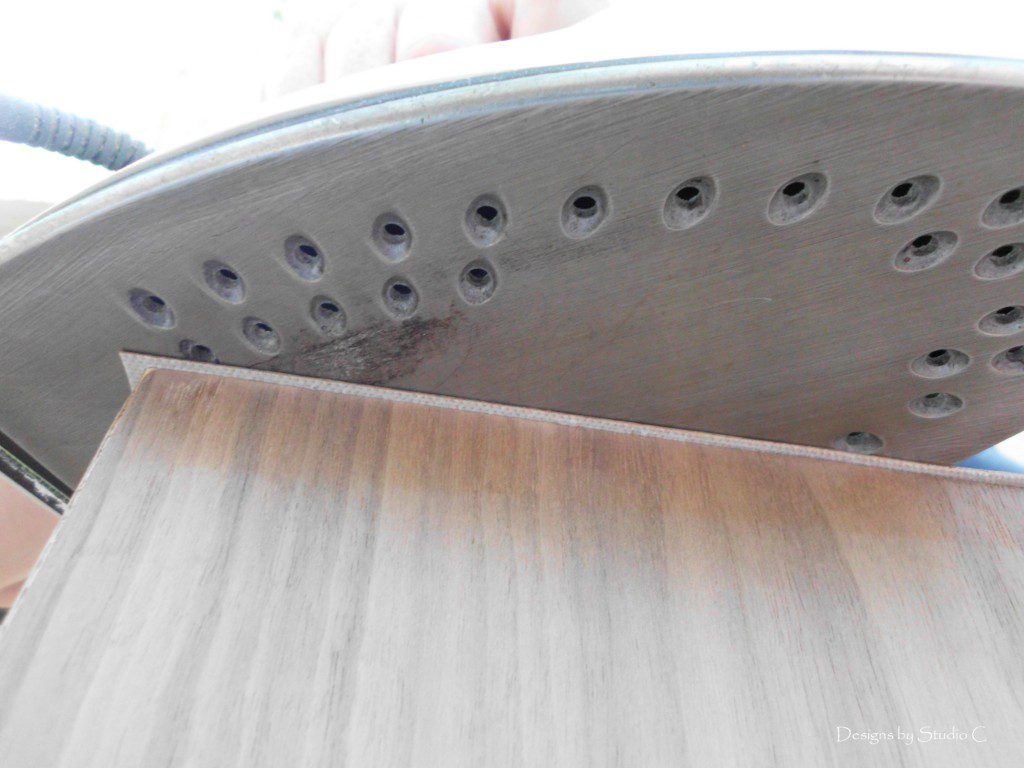

Set the iron on the “polyester” setting. The iron has to be hot enough to melt the adhesive. If it is too hot, it will make a huge mess!

Cut a piece of edge banding a little longer than the edge where it will be applied. Position it on the edge of the plywood and run the iron along the edge. Always let the adhesive cool before trimming it.

Once it is cool, use a pair of scissors to trim the overlapping part of the banding flush with the edge of the plywood.

To trim the long edges, start at one end and run the trimmer along the edge. I have a trimmer that cuts both sides at once. It is a little more expensive (I found mine on eBay) than the single edge trimmer but I find it saves a lot of time. Plus, refill blades are available!

Repeat the process for the top and bottom. Now, the plywood looks like a piece of solid wood! Sand the edges lightly with a piece of 220 grit sandpaper for a more finished look.

Have any questions about how to apply edge banding to plywood? Leave a comment below!

Originally posted 2012-08-08 08:00:16.

11 Comments

Is it really neccesary to use a special trimmng tool as opposed to a basic x-acto or utility knife?

An x-acto knife or utility knife can be used, if desired!

Pingback: Free Furniture Plans to Build a Hutch for a Desk

Pingback: three ways to finish the edges of plywood

Pingback: Build a Hutch for a Desk

Pingback: Three Ways to Finish the Edges of Plywood | Designs by Studio C

Pingback: Build a Hutch for a Desk | Designs by Studio C

Pingback: Plans to Build a Hutch for a Desk | Designs by Studio C

Pingback: Build an Ashworth 5 Drawer Dresser | Designs by Studio C

Pingback: Free Furniture Plans to Build a Cabinet | Designs by Studio C

Pingback: Build a Dreamy Bedside Table | Designs by Studio C