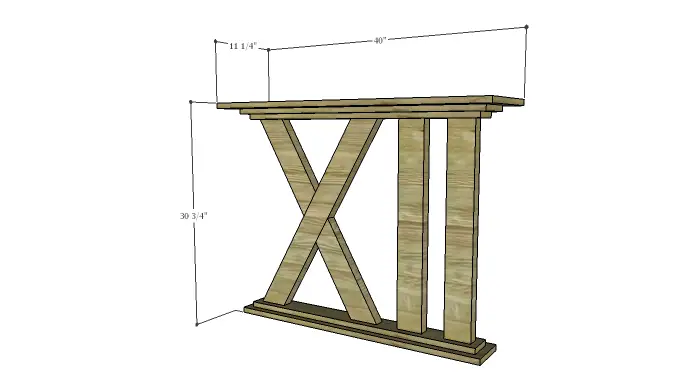

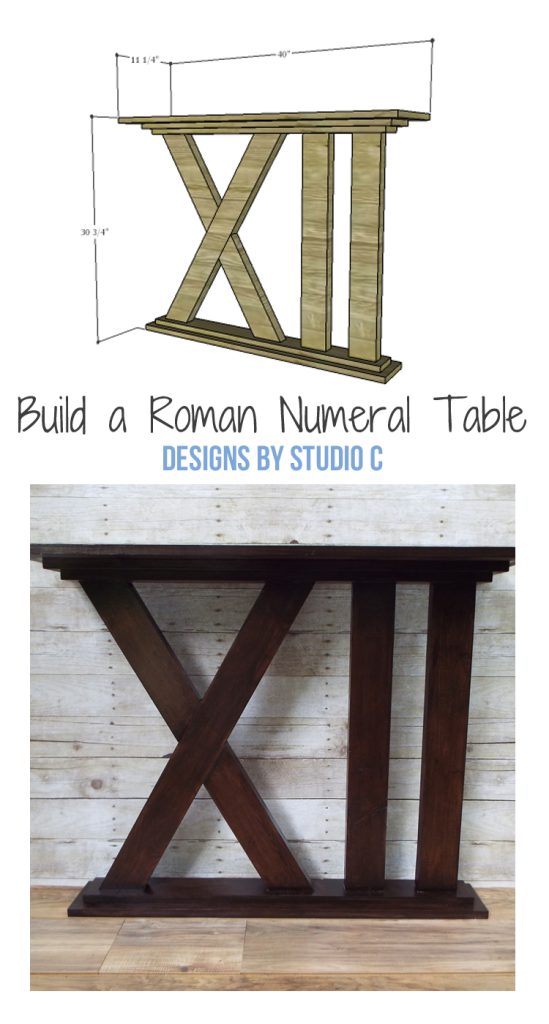

Build a Roman Numeral Console Table

A Unique and Easy to Build Console Table

I have always been fascinated with Roman numerals… To me, they are so unique and when I see them in the credits at the end of a movie (to mark the year the film was made), I like to challenge my kids to read them. They are actually pretty quick at it! Anyway, the DIY furniture plans to build a Roman Numeral Console Table feature the numerals as the legs. The legs are on a stacked base with a stacked top. I chose to paint and stain mine, and was able to build the table in a couple of hours!

Materials:

- 2-1/2″ pocket hole screws (<– affiliate link!)

- 1-1/4″ brad nails

- Wood glue

- Sandpaper (100, 150, 220 grits)

- Finishing supplies (primer & paint, or stain, sealer)

- Nail-on Teflon furniture feet

Tools Needed:

- Table saw, optional

- Miter saw or circular saw

- Drill

- Pocket hole jig

- Pneumatic brad nailer with compressor (or battery powered nailer)

- Sander

Lumber:

For the table as shown in the example:

- 1 – 1×3 at 6′

- 1 – 1×6 at 8′

- 1 – 1×12 at 4′

- 2 – 2×4 at 8′

Cut List:

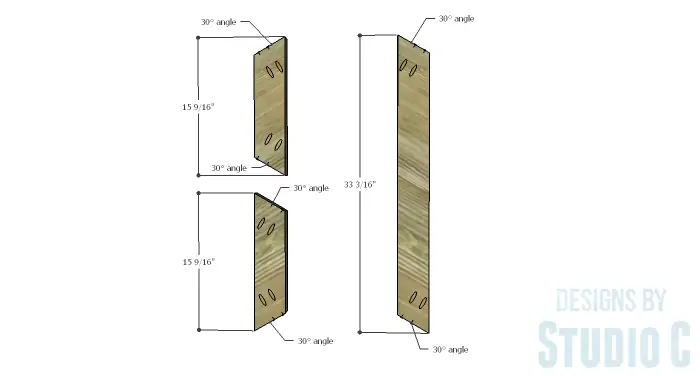

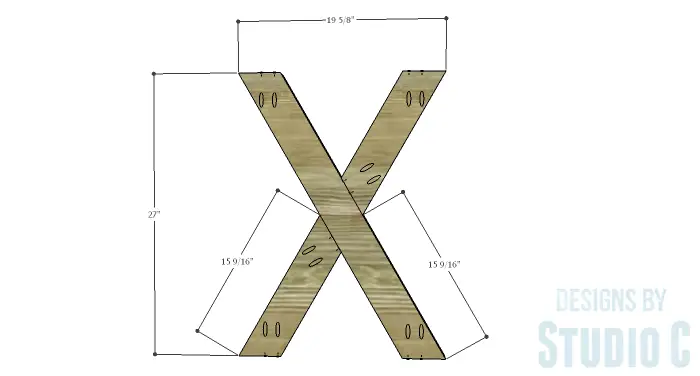

For X:

- 1 – 2×4 at 33-3/16″

- 2 – 2×4 at 15-9/16″

For I:

- 1 – 2×4 at 27″

For V:

- 2 – 2×4 at 28-1/8″

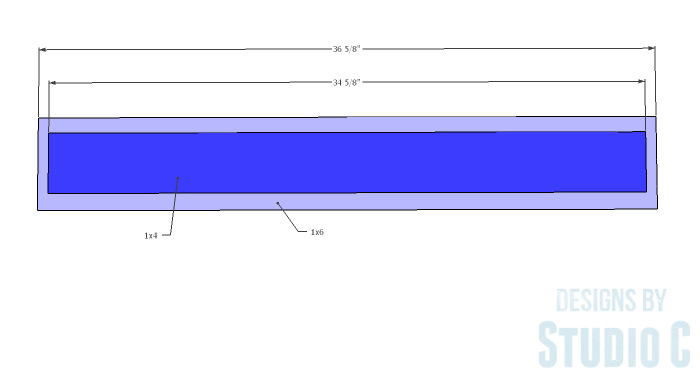

For the base:

- 1 – 1×4 at 34-5/8″

- 1 – 1×6 at 36-5/8″

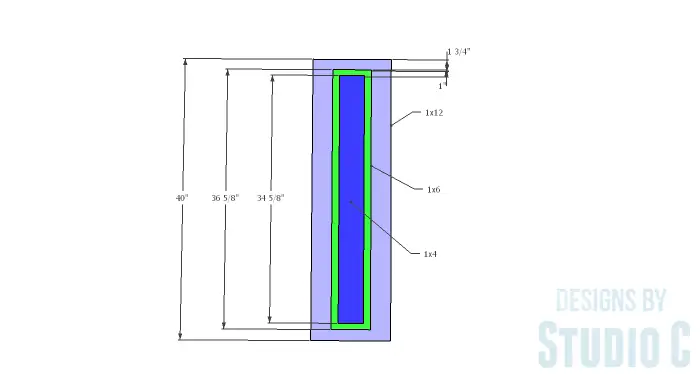

For the top:

- 1 – 1×4 at 34-5/8″

- 1 – 1×6 at 36-5/8″

- 1 – 1×12 at 40″

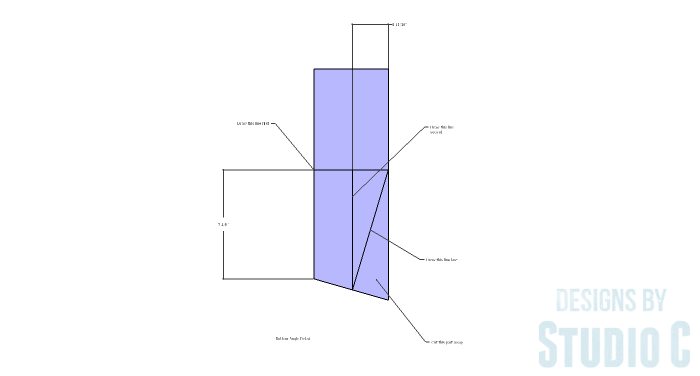

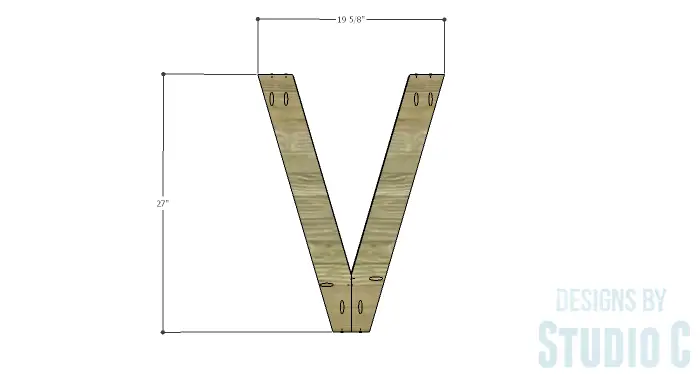

Click on the drawings for a larger view!

Notes about the project:

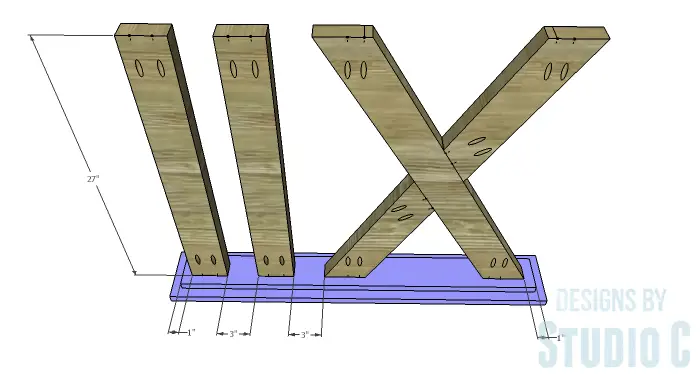

Though it wasn’t used in the example, I included plans for the number V (5) so that the table can be customized with special numbers. The top and bottom boards may need to be adjusted – the 1×3 boards are 1″ longer on each side than the letters when laid out, the 1×6 is 1″ longer on each side than the 1×3 and the 1×12 is longer by 3″ on each side (than the corresponding 1×6 below it). The numbers are spaced 3″ apart.

Step One

Cut the pieces for the number X (10). The angles cut in each end of the pieces is 30°. Set the pocket hole jig for 1-1/2″ material and drill pocket holes in the angled pieces as shown in the drawing.

Cut the pieces for the number I (1) and drill pocket holes in each end.

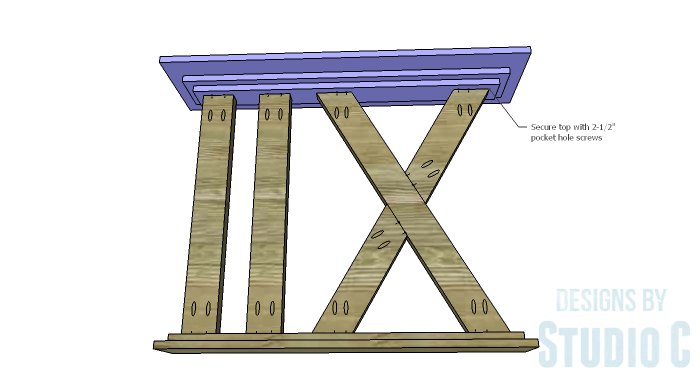

Step Two

Cut the pieces for the bottom. Apply glue to the bottom of the 1×3 piece and position it on top of the 1×6 piece – refer to the drawing for placement. Secure the 1×3 to the 1×6 using 1-1/4″ brad nails.

Secure the numbers to the bottom pieces using glue and 2-1/2″ pocket hole screws. The numbers are spaced 1″ from each end of the 1×3 with 3″ between them.

Step Three

Cut the pieces for the top. Apply glue to the bottom of the 1×6 and position it on the 1×12 – refer to the drawing for placement. Secure the 1×6 to the 1×12 using 1-1/4″ brad nails.

Apply glue to the bottom of the 1×3 piece and position it on top of the 1×6 piece again referring to the drawing for placement. Secure the 1×3 to the 1×6 using 1-1/4″ brad nails.

Secure the numbers to the top pieces using glue and 2-1/2″ pocket hole screws with the same spacing as the bottom.

Thoroughly sand and finish as desired. I used a stain and sealer in one in an Espresso color.

Nail-on Teflon feet or felt pads can be positioned on the bottom so that it doesn’t mar the floors. Also, if there are young children around, it may be a good idea to use 1″ angle brackets to secure the console table to the wall or floor.

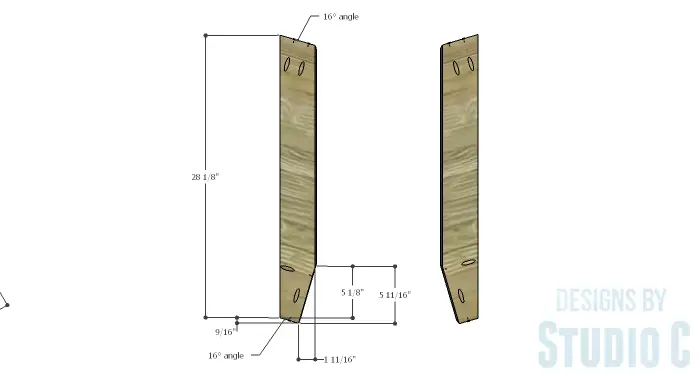

To make the number V (5):

Cut the pieces for the number V. Cut a 16° angle at each end of each piece. On the lower end of each piece, measure up 5-1/8″ from the higher end of the angle (the outside edge of the board) and draw a line across the board to the inside edge. Make a mark on this line 1-11/16″ from the inside edge and draw a line straight down to the angle. Draw a diagonal line from the inside edge at the first line down to where the line drawn at 1-11/16″ intersects the lower angle. Cut along this line with a jigsaw or bandsaw. Drill pocket holes as shown. Assemble the V using glue and 2-1/2″ pocket hole screws.

Have any questions about the DIY furniture plans to build a Roman Numeral Console Table? Leave a comment below!

Originally posted 2016-06-02 08:00:27.

I LOVE your table. Stumbled & Pinned! 🙂

Thank you so much, Marilyn! It was really easy to build… 🙂